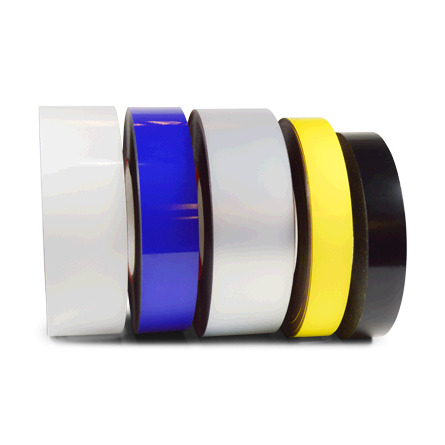

Here below you will find our various selection of our hand-picked ribbons.

The line of resin ribbons offers extreme durability against solvents and abrasions, so you can confidently choose the right ribbon for the right application.

We will gladly help you find the right ribbon to your product

The Epson LW-PX900 label printer is the future of economical and time-saving electronic label, heat-shrink tube, and bar-code printers.

- Saves on wasted tape with short 4mm lead margin*

- Fast print speeds of up to 35mm/sec

- Prints label widths up to 36mm (1.5″)

- Prints on shrink tube up to 21mm (7/8″) wide

- Crisp, clear 360 dpi printing resolution

- Print on die-cut square, circle, or oval supplies

- Cost-effective tape cartridges yield more labels

The LW-PX900 label printer features a high-speed, 360dpi print output that creates highly visible and detailed labels, bar codes and wire identification faster and with better detail than other printer models. A 4mm standard lead margin, and the ability to reduce tape waste down to 1mm is an industry leading cost saving feature.

Wax/resin ribbons are unique in formulation and function. The most critical quality they have to possess is the ability to print on a broad array of label substrates from high-end glossy paper to low-end synthetics. Here at TEXIT we use this formulation to print on our polyolfin based materials and label materials.

We will gladly help you find the right ribbon to your product

Wire harness labels provide important traceability information certifying that the wire harness has been manufactured in accordance

with appropriate government or certification laboratory standards. It is critical that the label remain in place and clearly legible throughout

the life of the product.

Pressure-sensitive films and adhesives are the ideal solution for wire harness labels. Pressure-sensitive films are rigid and provide excellent printability,

allowing the label to endure product use and abrasion while remaining legible. Specially formulated pressure-sensitive adhesives are

designed to bond well to rubber wire harnesses, ensuring that the label remains in place throughout the life of the product.

To meet the demanding requirements for wire harness labeling, look to pressure-sensitive films and adhesives.

■ 3.5 mil frosty clear vinyl film for easy application

■ A Permanent pressure-sensitive acrylic adhesive bonds well to a variety of surfaces

■ UL recognized under UL 969 – UL File – No. PGGU2.MH10170

Wire harness labels provide important traceability information certifying that the wire harness has been manufactured in accordance

with appropriate government or certification laboratory standards. It is critical that the label remain in place and clearly legible throughout

the life of the product.

Pressure-sensitive films and adhesives are the ideal solution for wire harness labels. Pressure-sensitive films are rigid and provide excellent printability,

allowing the label to endure product use and abrasion while remaining legible. Specially formulated pressure-sensitive adhesives are

designed to bond well to rubber wire harnesses, ensuring that the label remains in place throughout the life of the product.

To meet the demanding requirements for wire harness labeling, look to pressure-sensitive films and adhesives.

■ 3.5 mil frosty clear vinyl film for easy application

■ A Permanent pressure-sensitive acrylic adhesive bonds well to a variety of surfaces

■ UL recognized under UL 969 – UL File – No. PGGU2.MH10170

…

Thermal Transfer Printable Hole Tags are extruded from halogen free and flame retardant PUR (Thermoplastic Polyether-Polyurethane) material which is hydrolysis ” No break down in water” and micro organism resistant. Its extremely strong with high tear strength, suitable for a variety of indoor and outdoor applications where durable mark permanence is de facto standard. The hole tags are slipped on the wire or by direct fixation to the panel. The product is supplied as an all-in-one construction, where the extruded material also functions as the carrier. The markers are partially perforated for easy picking after printing and supplied on rolls for thermal transfer printing.

UV STABILITY DATA

Results of accelerated ageing testing are as a result of artficial lighting/illumination in a laboratory. Duration test is 500 hours, which equals 10 years of exposure.

Thermal Transfer Printable Circular Hole Tags are extruded from halogen free and flame retardant PUR (Thermoplastic Polyether-Polyurethane) material which is hydrolysis ” No break down in water” and micro organism resistant. Its extremely strong with high tear strength, suitable for a variety of indoor and outdoor applications where durable mark permanence is de facto standard. The circular hole tags are slipped on the wire or by direct fixation to the panel. The product is supplied as an all-in-one construction, where the extruded material also functions as the carrier. The markers are partially perforated for easy picking after printing and supplied on rolls for thermal transfer printing.

UV STABILITY DATA

Results of accelerated ageing testing are as a result of artficial lighting/illumination in a laboratory. Duration test is 500 hours, which equals 10 years of exposure.

Cable Markers in extruded from halogen free and flame retardant PUR (Thermoplastic Polyether-Polyurethane) material which is hydrolysis ” No break down in water” and micro organism resistant. Its extremely strong with high tear strength, suitable for a variety of in and outdoor applications where durable mark permanence is de facto standard. The labels are fixed to the cable or wire using cable ties at both ends. The product is supplied as an all-in-one construction, where the extruded material also functions as the carrier. The markers are partially perforated for easy picking after printing and supplied on rolls for thermal transfer printing.

UV STABILITY DATA

Results of accelerated ageing testing are as a result of artficial lighting/illumination in a laboratory. Duration test is 500 hours, which equals 10 years of exposure.

Cable Markers in extruded from halogen free and flame retardant PUR (Thermoplastic Polyether-Polyurethane) material which is hydrolysis ” No break down in water” and micro organism resistant. Its extremely strong with high tear strength, suitable for a variety of in and outdoor applications where durable mark permanence is de facto standard.

The markers are applied onto a thermal sensitive cardstock carrier roll, organised and easy to pick apply after printing.

Get your own logo and batch number printed directly on the liner for customised products.

Inbuilt quality control

Liner can be retained for QA/supervisor process control where your part and batch number can be printed directly on the liner.

UV stability data

Results of accelerated ageing testing are as a result of artficial lighting/illumination in a laboratory. Duration test is 500 hours, which equals 10 years of exposure.